Following my laser demonstration at the August meeting. I was asked to do an article giving further information for this site and for Revolutions. The magazine of AWGB.

This is the first draft of the article

John Douglas

Some technical information

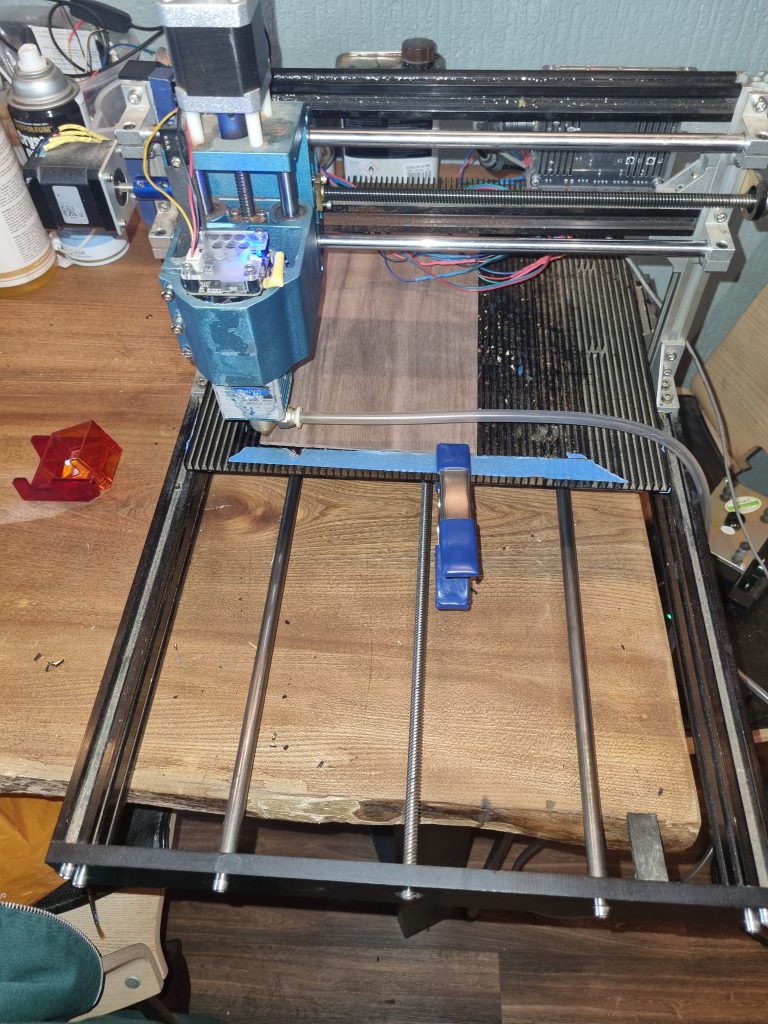

The laser machine is a home made 300 by 500mm laser bed fitted with a 40 watt output blue diode laser. Based on the readily available 3018 chinese laser but with extended X and Y axis. The machine can also take a spindle motor for 3d routing and carving.

Software

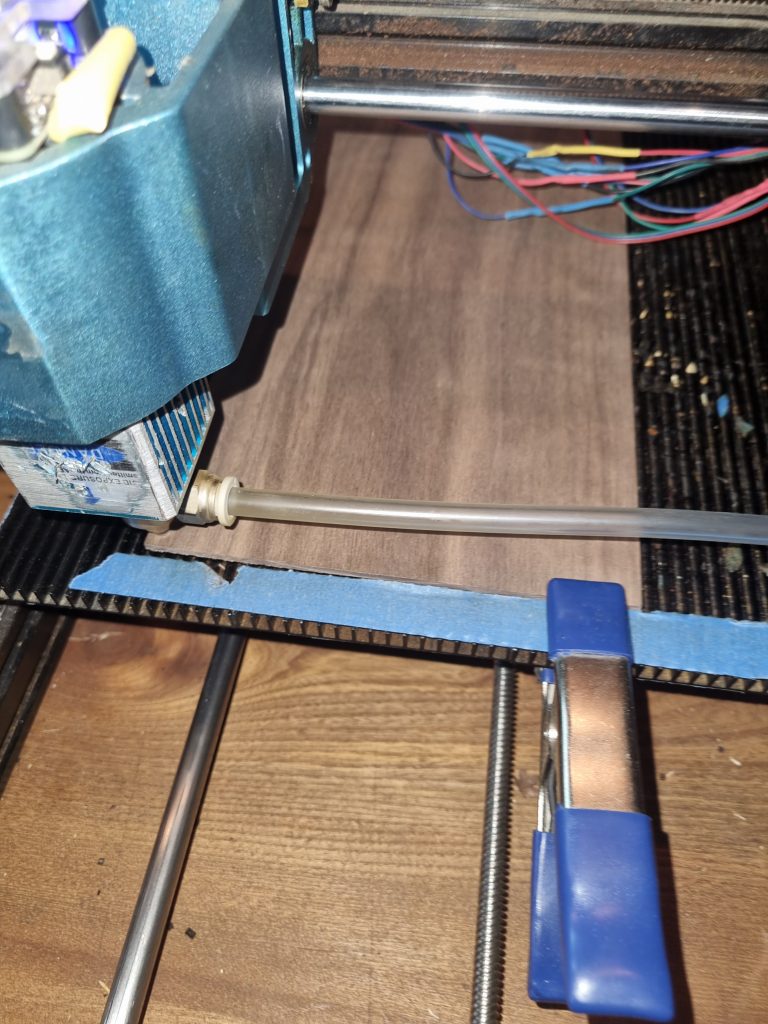

I use Lightburn or Laser GRBL Both are easy to use. Lightburn is my preference. I used the 4mm black walnut slips available from British Hardwoods. Although the machine was big enough to cut a full circle. Because of the size of the slips I set up the machine to cut the circle in 4 sectors. Here’s how I set up the software to cut the inlays. Drawing using Lightburn is very easy.

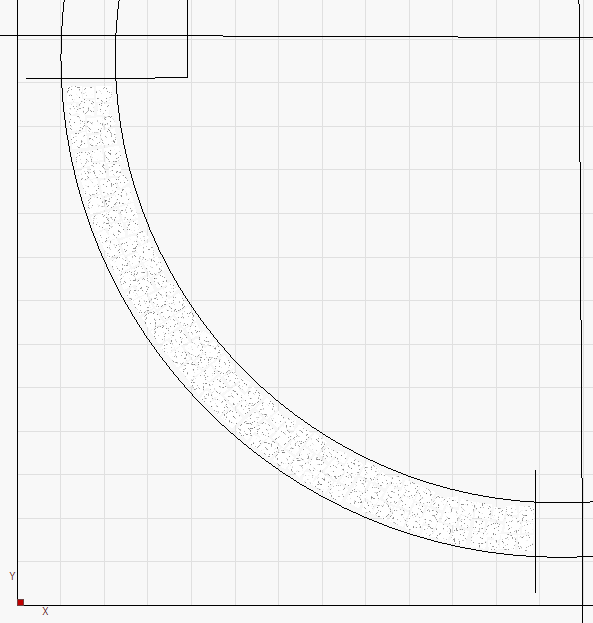

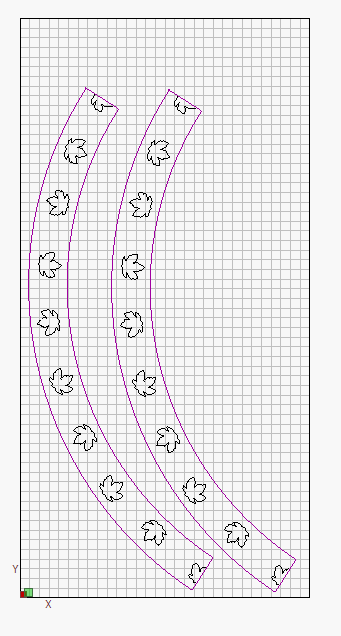

I drew two circles at the required diameters. I then trimmed them to produce a quarter of the circle. I drew a maple leaf and pasted into the circle

Duplicated to make two sections. This drawing was used to cut the walnut slips

Pushed together and placed on the bowl blank. The size was checked and the position marked on the blank

a recess was cut to hold the slips which were glued into the blank

the leaf shapes were filled using Milliput metallic epoxy paste.